Epiroc has confirmed that it has joined together with Boliden, Algoryx and Orebro University with a shared goal of achieving autonomous face drilling.

The equipment maker said the heart of the work for the involved parties will be the construction and employment of a digital twin of a mine – a simulated testing environment – for machine learning, thereby greatly reducing the need for physical testing.

As noted by Epiroc Underground Division Global Innovation Manager Oskar Lundberg, face drilling is already automated in part, via rig control systems following digital drill plans. However, in practice, the face topography in this is seldom accurate.

However, he added, finding a solution for autonomous face drilling will be a major step toward fully automated underground mining.

“The success of the blast is very much dependent on the quality of the drilling. We are trying to figure out if an autonomous system can achieve results that are comparable with or better than those of experienced operators,” he said.

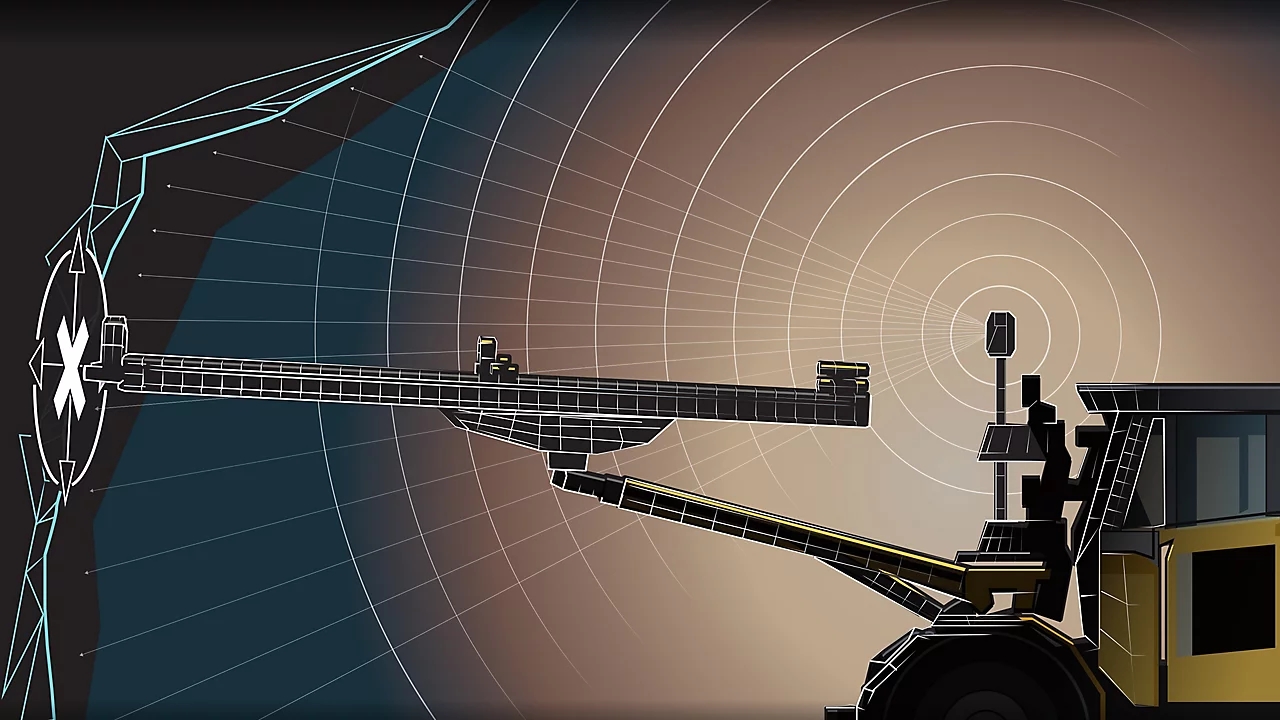

In this work, the groups will equip a Boomer face drill rig with a laser scanner and an AI system to scan and analyze the face before adjusting and applying the drill plan. To teach the system to identify potential problems and decide what changes should be made to the drill plan, the project constructs a simulated environment for running the thousands of scenarios necessary for the trial-and-error process of machine learning. After simulation training, the system graduates to an actual physical mine for the final tests.

To build the digital twin, an actual mine tunnel at Boliden is scanned, and the environment is then rendered in the Unity game engine. A large number of slightly randomized environments, including obstacles, are generated to provide different training scenarios. A digitalized version of the rig is inserted into the simulated environment, and a physics engine from Algoryx ensures that all forces affecting the rig are as close to reality as possible. A simulated laser scanner, with corresponding functionality to a real one, is added to the simulated rig.

From the system’s point of view, it is vital that the simulated environment resembles an actual mine as closely as possible. The digital twin does not have to look exactly like a mine but it has to scan like one. The simulated laser scans the simulated environment, generating a point cloud which the system then analyzes to look for potential problems and adjusts the drill plan accordingly.

The project is scheduled to run until 2025. Lundberg said the project to date has come a third of the way.

“As of now, we’ve entered an extremely active phase with a large number of ongoing activities. There’s full transparency between the partners, and we’re all focused on producing working solutions. As a bonus, we’re greatly increasing simulation competence within Epiroc.”

Source: Epiroc